HydroSense: Safeguarding Clean Energy Through AI and Next-Generation Sensors

The HydroSense project presents a revolutionary, AI-powered solution designed to address critical inefficiencies and risks within Hydro Power Plants (HPPs). These power stations currently face significant challenges, including the risk of unexpected accidents, high repair costs resulting from delayed inspection, and substantial energy waste. Specifically, HPPs experience an average daily energy loss of 8-15%. In the context of the Azerbaijani energy sector, the annual monetary loss attributed to energy inefficiency from exports alone ranges from $2.9 million to $5.5 million.

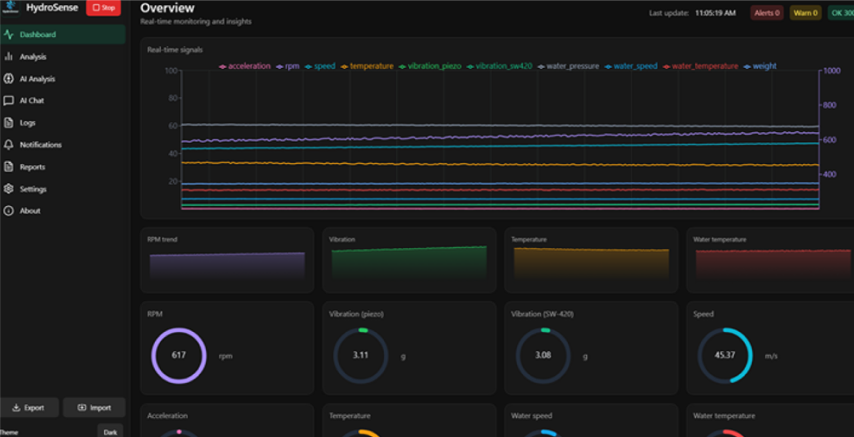

The Solution: Immediate and Intelligent System Monitoring

HydroSense provides a comprehensive, three-part technological solution to these problems. First, it integrates new-generation sensors to collect real-time, comprehensive operational data from critical infrastructure within the HPPs. Second, this vast stream of data is instantly processed and analyzed using sophisticated Artificial Intelligence (AI) algorithms, which can detect anomalies and predict potential failures far earlier than traditional inspection methods. Finally, the findings are delivered to HPP specialists via a simple, user-friendly mobile application, allowing for preemptive maintenance and immediate operational adjustments. By implementing this system, the potential financial loss is projected to be drastically reduced to between $0.3 million and $1.1 million annually.

Scaling and Impact

The team has outlined a phased development and market entry strategy, with an initial budget of $40,000 allocated for product preparation, covering device collaboration, system development, and additional expenses. A crucial Test Phase is planned for 2025-2026, which requires $200,000 in funding before the testing stage can commence. Following a successful test phase in 2027, the project targets global market entry, beginning with expansion into South Korea and the United States in 2026-2027. The successful deployment of HydroSense will not only minimize financial losses but also reduce operational downtime and extend the lifespan of critical clean energy infrastructure.

HydroSense and the Sustainable Development Goals (SDGs)

The HydroSense project directly contributes to global sustainability and climate action by focusing on the efficiency and reliability of clean energy infrastructure. This groundbreaking technology is essential for addressing the following United Nations Sustainable Development Goals (SDGs):

- SDG 7: Affordable and Clean Energy: By tackling the documented 8-15% daily energy loss and improving the operational efficiency of Hydro Power Plants, HydroSense directly contributes to target 7.3, which aims to double the global rate of improvement in energy efficiency. Ensuring that clean hydropower is utilized with minimal waste is vital for sustainable energy consumption.

- SDG 9: Industry, Innovation, and Infrastructure: The project embodies a commitment to building resilient infrastructure, promoting inclusive and sustainable industrialization, and fostering innovation. HydroSense uses advanced AI and new sensor technology to upgrade the maintenance of critical energy infrastructure, directly supporting target 9.4 on retrofitting industries for sustainability and greater resource-use efficiency.

- SDG 13: Climate Action: As a technology that maximizes the output and reliability of hydropower, a form of clean energy, HydroSense contributes to climate change mitigation. By reducing energy loss, it ensures that the power grid can rely more effectively on renewable sources, thus supporting global efforts to combat climate change and its impacts.

The successful and innovative development of the HydroSense project was significantly underpinned by the invaluable expertise of the Department of Electrical Engineering teachers and mentors. Their guidance, crucial for a system focused on monitoring Hydro Power Plants (HPPs), was instrumental in integrating the new-generation sensors and advanced control systems necessary for real-time operational data collection. This mentorship ensured the precise application of electrical engineering principles to detect anomalies, predict potential failures, and ultimately enhance the efficiency and reliability of clean energy infrastructure, directly tackling the challenge of 8-15% daily energy loss in HPPs.