BIO DIZEL: Clean Energy, Green Future

The BIO DIZEL project offers a critical, ecologically sound solution to one of the most pressing global challenges of our time: air pollution and climate change. The widespread use of conventional diesel engines contaminates the air, releasing microscopic particles into the environment that pose direct health risks by entering the lungs and bloodstream. Furthermore, traditional diesel is petroleum-based, and a significant environmental problem involves the improper disposal of waste oils, which are often dumped into sewage systems. This project addresses these issues head-on by introducing an affordable, high-quality, and ecologically sound alternative.

The Innovative Solution: Affordable Biodiesel

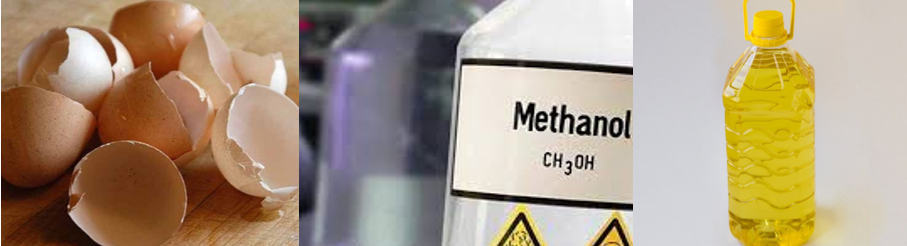

Biodiesel is a renewable, environmentally friendly liquid fuel designed to directly replace conventional diesel. It is derived from sustainable sources such as vegetable oils and animal fats. The primary objective of this project is to create an exceptionally cost-effective biodiesel by optimizing the chemical process of transesterification.

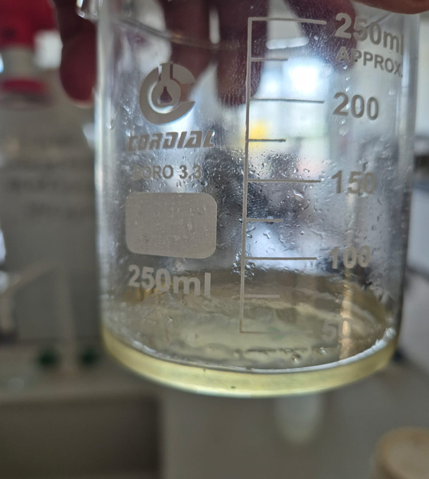

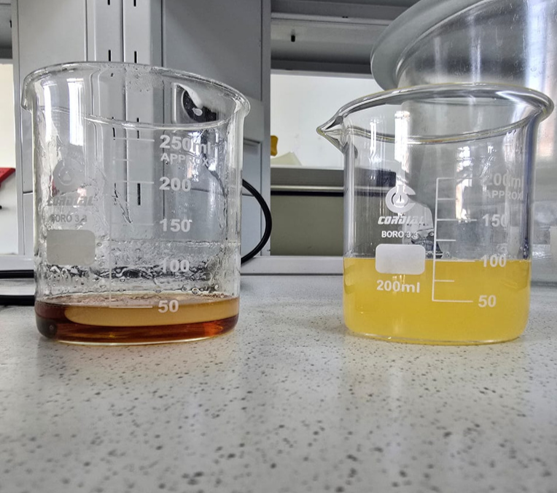

The project team performed several reactions to perfect their method. Initially, they found that a high temperature (70°C) caused an essential component, alcohol, to evaporate, leading to an unsuccessful outcome. They achieved a successful conversion by lowering the temperature to 40°C, which resulted in a separation into two layers of material, demonstrating the successful formation of biodiesel from both vegetable oil and animal fat.

Key Differentiator: Cost-Effective Production

The core innovation of the BIO DIZEL project lies in its ability to drastically cut production costs compared to existing industry standards.

Standard Production Method: The typical industry process for producing 1 liter of biodiesel relies on expensive chemicals like Sodium Hydroxide (NaOH). Using waste oil and methyl alcohol, this method results in a total production cost of approximately 1.27 AZN per liter.

BIO DIZEL's Method: The project successfully replaced the expensive NaOH catalyst with a common, environmentally friendly, and significantly cheaper alternative: Eggshell (CaO). By using Eggshell (CaO), the total production cost for 1 liter of biodiesel is reduced to just 0.69 AZN. This substitution lowers the overall cost of production by more than 45%, making the product economically competitive and sustainable.

Market Potential and Application

The global biodiesel market is substantial, valued at approximately $45 billion, with an expected annual growth rate of 5-6%. Key markets include the US, Brazil, Germany, and India. In Azerbaijan, the current biodiesel production volume is estimated at 50-60 thousand tons per year, translating to a market value of $50-60 million.

This affordable and clean fuel has broad application across multiple sectors:

Transport Sector: It can be used in diesel engine cars, public transportation, and marine transport.

Energy Production: It serves as a direct substitute for diesel in electric generators and heating systems, and in agricultural machinery.

Industrial Sector: It can be used as oil in hydraulic systems or as a fraction mixture with mineral diesel.

Ecological Applications: It is ideal for use in high-pollution risk areas and is specifically deployed to reduce carbon emissions.

BioDiesel and the Sustainable Development Goals (SDGs)

The BIO DIZEL project directly advances global sustainability by targeting multiple United Nations Sustainable Development Goals (SDGs), focusing on environmental health and resource efficiency:

- SDG 7: Affordable and Clean Energy: The core mission is to replace conventional fossil diesel with a readily available, renewable alternative (biodiesel from plant and animal fats). This directly supports the transition to cleaner energy systems for a sustainable future.

- SDG 12: Responsible Consumption and Production: The project demonstrates sustainable resource management by using waste oil as its primary raw material and preventing its harmful disposal into sewage systems. Crucially, the innovation of substituting costly chemicals (NaOH) with a biological waste product (Eggshell/CaO) minimizes resource use and promotes eco-friendly, circular-economy practices.

- SDG 13: Climate Action: By offering a clean-burning fuel, the project directly contributes to reducing air pollution and carbon emissions associated with traditional diesel use. This action is vital for mitigating climate change and its devastating impacts.

Future Vision

The future of the BIO DIZEL project is centered on three core principles: Economical, Ecologically Clean, and Reliable. The team's primary goals are to further optimize the production process for market scaling, expand the use of biodiesel across various sectors, and establish strategic partnerships. The ultimate mission is to counteract the severe problems caused by conventional diesel, foster an ecologically healthy future, and secure energy from sustainable, renewable sources.